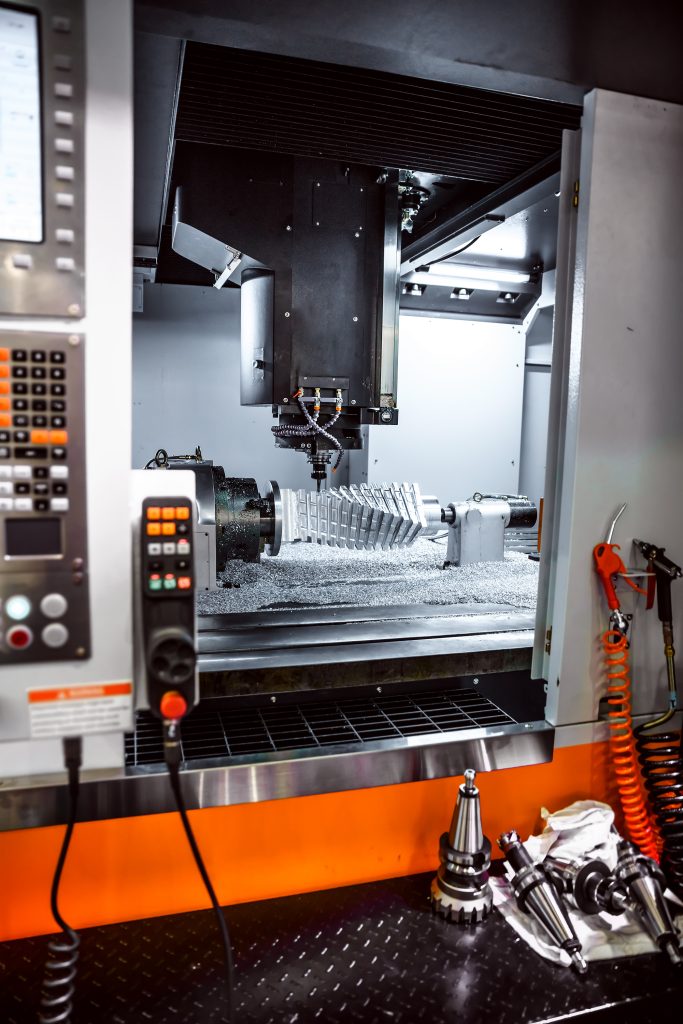

CNC machining, or Computer Numerical Control, has revolutionized the manufacturing industry, including plastics engineering. This advanced technology offers a number of advantages that make it the preferred choice for many manufacturing processes. Below are some of the key benefits of CNC machining in plastics engineering.

High precision and accuracy

One of the most prominent advantages of CNC machining is its high precision and accuracy. By using computer-controlled machines, manufacturers can create complex and detailed parts with extremely tight tolerances. This is especially important in plastics engineering where precise dimensions and shapes are often crucial to the function and quality of the product.

Reproducibility

CNC machining ensures consistent quality over large production runs. Once a design has been programmed into the CNC machine, the same part can be reproduced over and over again with the same precision. This minimizes the risk of error and ensures that all parts meet the specified requirements.

Flexibility in design and materials

CNC machines are very flexible in terms of design and can process a wide range of materials. In plastics engineering, CNC machining can be used to create components from a variety of plastics, including thermoplastics and thermosets. The machine's software can be easily adjusted to accommodate changes in design, allowing rapid prototyping and testing of new ideas.

Cost-effective production

Although the initial cost of installing CNC machines can be high, the long-term cost-effectiveness is significant. Automation reduces the need for labor and minimizes material waste through precise machining. In addition, the need for post-processing is reduced due to the high accuracy of the parts produced, further reducing production costs.

Improved product quality

CNC machining results in high-quality parts with smooth surfaces and precise dimensions. This is especially important in applications where the aesthetics and functionality of plastic parts are critical, such as in medical devices, automotive, and consumer products. The high quality of the machined parts contributes to longer life and better performance of the end products.

Reduced lead time

Automation and efficient programming allow CNC turning & CNC milling to complete production cycles faster than traditional machining methods. This results in shorter lead times from design to finished product, which is a crucial factor in today's fast-paced market environments. The ability to quickly respond to customer needs and market changes gives companies a competitive advantage.

Miljövänlighet

CNC-bearbetning bidrar till en mer miljövänlig produktion genom att minska materialspill och optimera användningen av resurser. Den exakta kontrollen över bearbetningsprocessen innebär att mindre material går till spillo, och energiförbrukningen kan ofta optimeras för att minimera miljöpåverkan .

Summary

CNC machining offers a range of advantages in plastics technology, including high precision, reproducibility, flexibility, cost-effectiveness, improved product quality, reduced lead time and environmental friendliness. By taking advantage of these advantages, companies in the plastics industry can improve their production processes and create high-quality products that meet market demands.

For more detailed information about our CNC machining services, contact us for a consultation on how we can help your company benefit from this advanced technology.